PicoGK — a compact and robust open-source geometry kernel for Computational Engineering

LEAP 71 is committed to Free and Open-Source Software (FOSS). We believe, that foundational technologies, like many computer algorithms, programming languages, and increasingly AI models, should be free for everyone and available in source code form. The computational geometry kernel that lies at the basis of Computational Engineering, is such a technology.

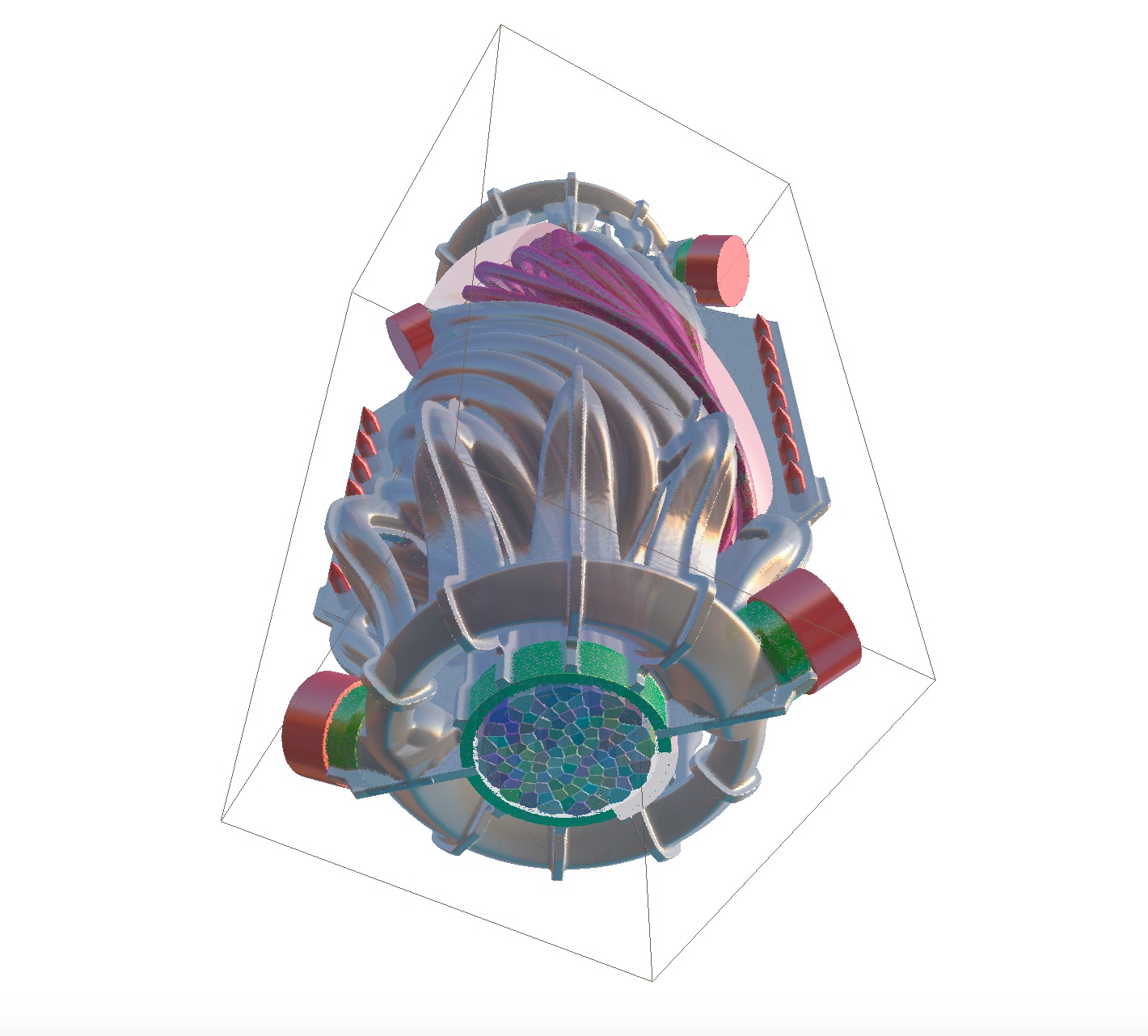

PicoGK (“peacock”) is a compact geometry kernel tailor-made for Computational Engineering. All of LEAP 71’s Computational Engineering Models and the resulting objects are based on PicoGK. PicoGK incorporates other Free and Open-Source projects, notably OpenVDB. The PicoGK viewer is based on GLFW, an open-source 3D user interface toolkit.

PicoGK stands for Pico (tiny) Geometry Kernel and provides an intentionally reduced but robust instruction set that can be used by Computational Engineering Models. LEAP 71 is committed to providing more open-source code in the future, to enable wide-spread adoption of this new paradigm, which, we think, is going to change the profession of engineering forever.

The first module that we are releasing in addition to PicoGK, is the LEAP 71 ShapeKernel, an abstraction layer for computational geometry, that makes it easier to build sophisticated parts.

The fundamental PicoGK Runtime module is written in C++. The higher level PicoGK code and the LEAP 71 ShapeKernel are written in C#, an elegant, high-performance, strongly-typed language, which gives us the power and confidence to create sophisticated algorithms that generate advanced technical objects.

PicoGK is actively developed and maintained by LEAP 71, and available for free under the permissive Apache 2.0 open-source license, which allows both commercial and non-commercial use.

By making PicoGK and other parts of our technology stack widely available, we hope to contribute to the adoption of this new paradigm and start building an active community of Computational Engineers.

To explore the PicoGK source code and get started, please head over to the LEAP 71 GitHub.

Our large #ComputationalEngineering Model, @noyron.ai lies at the core of all engineering work we do with our customers. Noyron abstracts general engineering logic, provides physics frameworks, such as thermal models, and automates the generation of complex geometry using @picogk our compact and robust #opensource geometry kernel. #Noyron builds machines.

#multimaterial #additivemanufacturing will allow us to build the next generation of machines, but it needs #ComputationalEngineering to generate the complex geometries required. Last year we worked with the @fraunhofer.igcv on perfecting their experimental steel/copper printing process. In the end the most complex object was this regeneratively cooled #aerospike rocket engine.

Our large #ComputationalEngineering Model, @noyron.ai lies at the core of all engineering work we do with our customers. Noyron abstracts general engineering logic, provides physics frameworks, such as thermal models, and automates the generation of complex geometry using @picogk our compact and robust #opensource geometry kernel. #Noyron builds machines.

#multimaterial #additivemanufacturing will allow us to build the next generation of machines, but it needs #ComputationalEngineering to generate the complex geometries required. Last year we worked with the @fraunhofer.igcv on perfecting their experimental steel/copper printing process. In the end the most complex object was this regeneratively cooled #aerospike rocket engine.

© 2024 by LEAP 71 — All Rights Reserved